My Patents on Automated Defect Detection for Turbine Blade Manufacturing

Overview

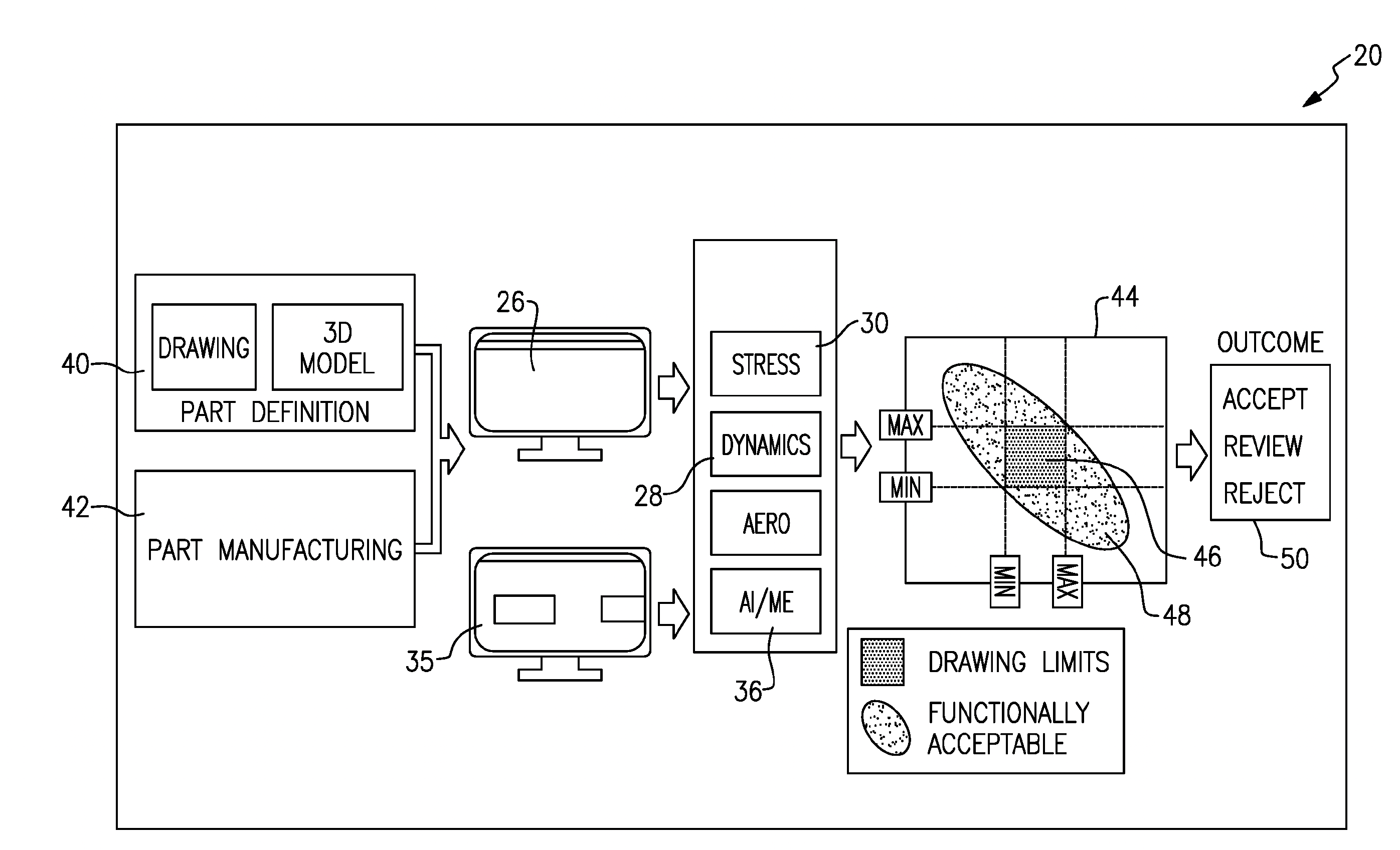

My team and I developed an automated defect detection system for airplane turbine blade manufacturing, which we called Rapid Part Assessment.

The Problem

When a manufactured part fails inspection, it isn't necessarily unusable. However, proving that a part remains safe and within functional acceptance requires significant analysis effort. Our goal was to create a machine learning surrogate model that reduces analysis time while maintaining safety guarantees.

Our Approach

We partnered with aerodynamics, dynamics, and stress experts to evaluate aerofoil shapes. The experts graded aerofoil shapes on a Likert scale of part acceptance.

We performed k-fold cross validation to generate training and validation splits. For each fold, we trained two models:

- Tabular model — trained on engineered features of the aerofoil shapes

- Computer vision model — trained on plotted images of aerofoil shapes within machine tolerance bands, using an ImageNet-pretrained backbone fine-tuned on aerofoil data

The models from each fold were ensembled together to classify part acceptance. Each full aerofoil had measurements taken at different stations (heights along the part). The model classified the shape at each station and aggregated results to produce an overall part rating. A held-out test set was used to assess final model performance.

Resolving Expert Disagreement

One challenge we encountered was disagreement among expert ratings. To address this, we built a web application that displayed an aerofoil alongside its rating and the n-nearest neighbor aerofoil shapes with their associated ratings. This allowed experts to see where their ratings differed from similar parts.

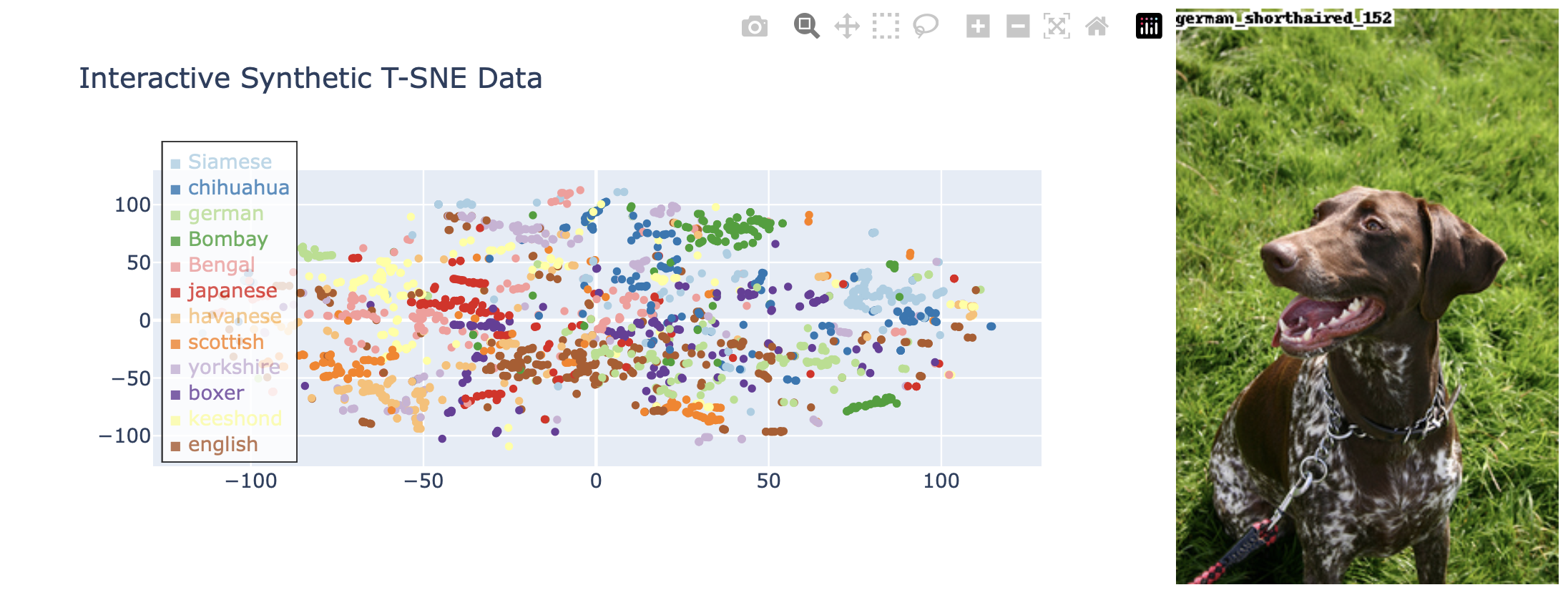

To find nearest neighbors, we removed the classification head from the trained model. The penultimate layer produced vector embeddings, which we compared using cosine similarity to identify the n-nearest neighbors. This was retrieval-augmented generation before LLMs made it popular.

To visualize the embedding space, we projected the vectors to two dimensions using t-SNE. An interactive Plotly graph allowed users to quickly identify where ratings did not match an aerofoil's peers and adjust accordingly.

Note: Aerofoil geometries are proprietary, so placeholder image is shown.

Data Integrity and Deployment

Data integrity was essential throughout the project. All data labels and relabels were tracked systematically.

Once the models and input data met safety requirements, the system was released into production.

Patents

This work was developed in partnership with Pratt & Whitney Canada. I am the lead inventor on this patent and a co-inventor on four additional patents:

Summary

We applied machine learning and MLOps best practices to aerospace manufacturing approximately three to four years ago, resulting in multiple patents protecting this approach.